Who Creates the Final Pre Incident Plan Drawings

- Refer to the ASHRAE Epidemic Task Force Transportation Guidance for additional data

General Operations References | Return to Summit

Guidance from cognizant authorities should be followed to the extent possible. Select guidance that is likely applicable for educational facilities includes:

- United States CDC Readiness and Planning Tool to Prevent the Spread of COVID-19 in M-12 Schools.

- This reference provides recommendations for policies, full general operations, response protocols, communications, etc.

- United states of america CDC Guidance for Chiliad-12 Schoolhouse Administrators on the Use of Cloth Face Coverings in Schools and Additional Considerations Table.

- These documents provide guidance for K-12 facilities in the use of fabric face coverings.

- United States CDC Considerations for Institutions of College Education.

- This reference provides general information, gamble assessment guidance, and recommendations for higher education institutions.

- United States CDC Guidance for Cleaning and Disinfecting.

- This reference provides cleaning guidance for multiple building types and should exist applicative to most K-12 and college educational activity spaces.

- WHO Communication on the use of masks in the context of COVID-nineteen.

- Background for recommendations associated with masks or confront coverings and recommendations for use under different circumstances.

- Harvard T.H. Chan Schoolhouse of Public Health – Schools For Health

- Risk reduction strategies, guide to checking ventilation, classroom calculators.

- Guidance from individual states or territories (United States):

- Johns Hopkins Academy eSchool+ Initiative – Assay of Reopening Plans.

- This reference includes bones information on land K-12 reopening plans and links to data from private states where specific guidance and requirements can be located.

- Johns Hopkins Academy eSchool+ Initiative – Assay of Reopening Plans.

Determining Building Readiness and Operations for Existing Facilities to Reoccupy Subsequently Shut-Downward due to Pandemic | Return to Top

These recommendations and strategies are organized in order from uncomplicated first steps, more involved adjacent steps and then more long-term improvements

- Create a Commune or Campus Health and Safety Committee that includes all stakeholders (environmental wellness and safety, administration, educational activity staff, operations staff, local healthcare providers, etc.)

- Develop policies for staff and contractor PPE requirements for completing work at facilities that follow local authority, CDC, and OSHA guidelines for the proper use of Personal Protective Equipment (PPE).

- Where semi-annual / almanac scheduled maintenance on the equipment can be performed safely, do not defer this maintenance bike.

- Where worker safety could be at risk, defer semi-annual/ annual maintenance on the equipment up to threescore days until worker safety tin be accomplished.

- During the summertime period before occupancy perform Checklist No. i Summer Checklist for Fall Showtime of Classes.

- Operate all HVAC in occupied mode following minimum periods prior to resuming full occupancy:

- Whatsoever time staff or others are in the building.

- 24 hours if systems have operated during closure period.

- Up to one week prior to occupancy if systems take been shut down to bring temperature and humidity under control prior to occupancy.

- During the week prior to occupancy perform Checklist No. ii Startup Checklist for HVAC Systems Prior to Occupancy.

Checklist No. 1: Checklist for Unoccupied Buildings Prior to Occupying | Return to Height

Review design guidance for potential system modifications to comply with this guidance.

Review air distribution conditions of existing spaces (look for covered diffusers, blocked return grilles, overly closed supply diffusers/registers and return/exhaust grilles creating short cycling, possible measurements of airflows by commissioning or balancing professionals, possible review of overall system configuration by pattern professional, etc.)

Review existing Indoor Air Quality bug, if whatsoever, records of documents and investigate current status of complaint and accost any deficiencies identified, if possible.

General inspection of spaces to place any potential concerns for water leaks or mold growth that could negatively impact occupant wellness.

Bank check all lavatories and sinks for correct functioning and ensure soap dispensers are functional and adequate supply of lather is available to allow for proper handwashing.

Coordinate with local utilities to identify when buildings volition exist restarted, identify when systems will be operated (if dissimilar than prior operations) and identify that demands may increase (primarily electric merely gas may apply as well for some facilities).

Review control sequences to verify systems are operating according to this guidance to maintain required ventilation, temperature and humidity conditions to occupied areas.

Address or articulate existing alarms from Building Automation Systems/Building Direction Systems to permit for recognition of new alarms that may impact building indoor air quality and consider warning hierarchy.

Review command sequences to verify systems are operating according to this guidance to maintain required ventilation, temperature and humidity conditions to occupied areas.

- Accost or clear existing alarms from Building Automation Systems/Edifice Management Systems to allow for recognition of new alarms that may touch building indoor air quality and consider alarm hierarchy.

- Consider completing preventative and deferred maintenance projects not straight related to pandemic, but potentially improving facility IEQ.

Checklist No. 2: Startup Checklist for HVAC Systems Prior to Occupancy | Return to Tiptop

Maintain proper indoor air weather condition (temperature and humidity) to maintain occupant comfort (refer to ASHRAE Standard 55), and to limit potential for mold growth in edifice structure and finishes

Review potential for maintaining space relative humidity betwixt 40% and 60%, which may reduce potential for airborne viral manual

Humidification during heating flavor in cold climates creates meaning potential for condensation in/on building envelope components – addition of, or modification to, humidification in these areas should be reviewed by competent professionals before changes are incorporated

Tendency and monitor temperature and humidity levels in each space to the extent possible and within the capability of BAS, portable data loggers and handheld instruments.

Verify proper separation between outdoor air intakes and exhaust discharge outlets to prevent/limit re-entrainment of potentially contaminated exhaust air (mostly minimum of ten-foot separation - comply with local code requirements).

Consider having airflows and edifice pressurization measured/balanced by a qualified Testing, Adjusting and Balancing (TAB) service provider.

Consider having airflows and system capacities reviewed by pattern professionals to determine if additional ventilation can be provided without adversely impacting equipment performance and building Indoor Environmental Quality (IEQ).

Measure building force per unit area relative to the outdoors. Adjust edifice air flows to prevent negative pressure differential.

Verify coil velocities and coil and unit discharge air temperatures required to maintain desired indoor conditions and to avoid moisture conduct over from cooling coils.

Review outdoor airflow rates compared to the most electric current version of ASHRAE Standard 62.1 or current state-adopted code requirements.

Filtration in all mechanical equipment:

Verify filters are installed correctly.

Develop standards for frequency of filter replacement and type of filters to be utilized.

Select filtration levels (MERV ratings) that are maximized for equipment capabilities, use MERV xiii if equipment allows, while assuring the pressure driblet is less than the fans capability. Run across Filtration Upgrades.

Disable Demand-Controlled Ventilation (DCV) systems using Carbon Dioxide (CO2) sensors where feasible:

Either disable control sequence or arrange setpoints to be at or near ambient outdoor CO2 levels (typically between 400 and 500 ppm).

Trend and monitor levels continuously if controls system is capable of doing so (use portable data loggers and handheld instruments and document readings where needed to demonstrate compliance with Commune or Campus requirements).

Consider adjusting to maximize outdoor air or disabling operation of DCV if it will non adversely bear upon functioning of overall arrangement (Temporary recommendation while operating under infectious disease crunch).

Systems incorporating variety into sizing may crave DCV to maintain ventilation to occupied spaces – consideration should be given to system capabilities and outdoor air flow rates should be maximized.

Perform initial air flush of all spaces prior to occupants re-entering building:

Mechanical systems should operate in occupied mode for minimum catamenia of one week prior to students returning (may be completed at same time as teachers start returning to edifice) while assuring the outside air dampers are open.

Domestic h2o systems shall exist prepared for use:

Systems should be flushed to remove potential contaminants from stagnant equipment, pipe, fixtures, etc.

Domestic common cold-h2o systems should be flushed with all fixtures on a branch of pipage opened simultaneously for a minimum menstruation of five minutes – preferred approach is to have all building fixtures open at aforementioned fourth dimension if possible – if non, intendance should be taken to ensure catamenia charge per unit is adequate to flush piping mains and co-operative lines.

Domestic hot water systems should exist flushed with all fixtures on a co-operative of piping opened simultaneously for a minimum period of 15 minutes – preferred arroyo is to have all edifice fixtures open at same time if possible – if not, care should be taken to ensure flow charge per unit is acceptable to flush pipage mains and co-operative lines.

Reference Standard 188 and Guideline 12

Equipment and System Specific Checks and Verifications During the Academic Yr | Return to Pinnacle

Cleaning and Air Flush: Daily

Flush spaces between occupied periods for a elapsing sufficient to reduce concentration of airborne infectious particles by 95%. For a well-mixed space, this would require 3 changes of infinite book using outdoor air (or equivalent outdoor air including the effect of filtration and air cleaners). In lieu of calculating the air change rate, pre- or postal service-occupancy flushing periods of ii hours may be used since this should be sufficient for most systems meeting minimum ventilation standards.

Cleaning:

All areas that have been occupied afterwards previous cleaning efforts should exist re-cleaned.

All restrooms should be thoroughly cleaned.

All food preparation areas should be thoroughly cleaned.

Any spaces not previously cleaned should have all accessible surfaces properly cleaned.

Boilers: Monthly

For systems with Steam Boilers, develop a schedule that provides minimum supervision on-site.

Perform chemical testing of organisation water. Verify water treatment target levels are being maintained.

For systems using fuel oil:

Bank check fuel pump for proper operation.

Inspect fuel filter; clean and verify proper functioning.

For systems using natural gas:

Check gas force per unit area, gas valve operation, and combustion fan operation.

Check for bear witness of leakage of fuel supply, heat transfer fluid, and flue gas.

Verify proper performance of safe devices per manufacturer's recommendations.

Chilled Water, Hot Water and Condenser H2o Systems: Monthly

Perform chemical testing of system h2o. Verify h2o treatment target levels are existence maintained.

Cheque the control system and devices for evidence of improper operation.

Verify control valves operate properly.

Check variable-frequency drives for proper operation.

Air Cooled Chillers: Monthly

Check the refrigerant system for evidence of leaks.

Check and clean fan blades and fan housing.

Check coil fins and check for damage.

Bank check for proper evaporator fluid catamenia and for fluid leaks.

Water Cooled Chillers: Monthly

Check the refrigerant system for evidence of leaks.

Bank check for proper evaporator and condenser fluid flow and for fluid leaks.

Cheque compressor oil level and/or pressure on refrigerant systems having oil level and/or pressure measurement ways.

Cooling Towers and Evaporative-Cooled Devices Monthly

Perform chemical testing of system h2o. Verify water treatment target levels are beingness maintained.

Bank check chemic injector device for proper functioning.

Check conductivity and other sensors for proper readings.

Bank check the water organization ultraviolet lamp, replace bulbs as needed (if applicable).

Check the command system and devices for testify of improper performance.

Cheque variable frequency drive for proper operation.

Check for proper condenser water flow and for leaks.

Check for proper damper operation.

Inspect pumps and associated electric components for leaks and normal operation.

Verify control valves operate properly.

Steam Distribution Systems: Monthly

Perform chemical testing of organisation condensate and feed h2o.

Bank check pipe for leaks.

Cheque steam traps and condensate return units for proper operation.

Cheque safe devices per manufacturer'due south recommendations.

Verify control valves operate properly.

HVAC Water Distribution Systems: Monthly

Perform chemical testing of system water. Verify h2o handling target levels are being maintained.

Check for proper fluid catamenia and for fluid leaks. If necessary, vent air from system high points and

Verify backflow preventers and pressure regulating valves on makeup water lines are functioning properly.

Check expansion tanks and bladder type pinch tanks have not go waterlogged.

Verify control valves operate properly.

Pumps: Annually

Inspect pumps and associated electric components for proper operation.

Check variable-frequency drive for proper operation.

Check the control system and devices for evidence of improper operation.

Air Treatment Units: Monthly

Cheque for particulate aggregating on filters, supercede filter every bit needed.

Check ultraviolet lamp, replace bulbs equally needed (if applicative).

Bank check P-trap on drain pan.

Check the control system and devices for evidence of improper performance.

Check variable-frequency drive for proper operation.

Check drain pans for cleanliness and proper slope.

Verify control dampers operate properly.

Confirm AHU is bringing in outdoor air and removing exhaust air as intended.

Verify filters are installed correctly.

Follow filter replacement policy.

Review condition of cooling coils in air handling equipment – if issues with condensate drainage are identified or biological growth is identified, corrective action should be taken to clean or repair.

Roof Tiptop Units: Monthly

Check for particulate accumulation on outside air intake screens and filters. Replace filter as needed.

Cheque ultraviolet lamp, replace bulbs as needed (if applicable).

Cheque P-trap.

Check drain pans for cleanliness and proper gradient.

Check the control system and devices for evidence of improper performance.

Bank check variable frequency bulldoze for proper operation.

Check refrigerant system for leaks.

Check for evidence of leaks on gas heat department heat-exchanger surfaces.

For fans with belt drives, audit belts and adjust as necessary.

Verify control dampers operate properly.

Unitary and Single Zone Equipment (For example: Wall Hung Units, Unit of measurement Ventilators, Mini-Splits, Packaged Terminal Air Conditioners, H2o-Source Heat Pumps, Fan Gyre Units):

Monthly

Check for particulate accumulation on filters, supersede filter as needed.

Check P-trap.

Check drain pans for cleanliness and proper gradient.

Check the command organisation and devices for evidence of improper operation.

Verify control dampers operate properly.

New/Modified Facility Design Recommendations | Return to Top

Introduction

This guidance has been formulated to assist designers retrofit and program for the improvement of indoor air quality and to slow the transmission of viruses via the HVAC systems. The underlying try of the designer should be to increase exterior air to the spaces, treat return air and or supply air to spaces via mechanical filtration and maintain indoor comfort as divers past the pattern temperature and relative humidity.

This guidance should be applied to each unique climate zone, unique school building and HVAC system. All retrofits and modifications must not contradict ASHRAE 62.1 guidelines and must continue to meet or exceed applicable codes and standards. The designer needs to piece of work closely with the local school system to work in conjunctions with new operational protocols and schoolhouse operations.

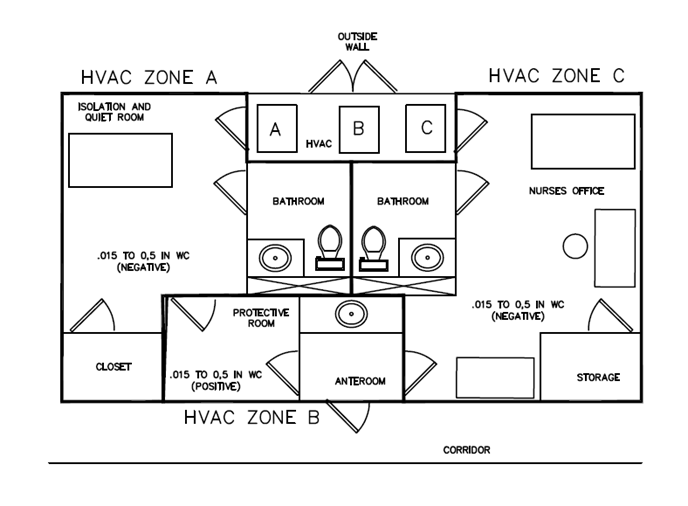

Nurse role suite blueprint should follow health care facilities design practices as described in standards such as ASHRAE Standard 170 and other applicable guidelines and design data.

Designer Guidelines – Full general School | Return to Meridian

Temperature and Humidity Pattern Criteria

- Wintertime classroom pattern guidelines 72 F/40- 50% RH

40- fifty% RH in wintertime is primary guidance via humidifiers/active humidification (central or local, depending on the classroom/space system). The humidity minimum, humidifier, and sensor location should exist made after consultation with your ASHRAE professional regarding the envelope design due to the potential for condensation inside the building envelope. - Summer classroom blueprint guidelines 75 F/50%-lx% RH

Designing to 50% RH in summer is primary guidance, depending on the classroom system.

Ventilation Design Criteria/Guideline

- Follow current ASHRAE 62 standard or local ventilation standards for minimum outside air requirements.

- Consider increasing exterior air capacities beyond lawmaking minimum based on analysis completed by a qualified HVAC professional.

- For retrofitting or replacing an existing AHU, verify equipment provides required minimum exterior air to all occupied spaces.

- For Dedicated Outdoor Air Systems (DOAS) that are beingness replaced, size unit of measurement with the post-obit in listen:

- Consider increasing capacities beyond code minimum for ventilation.

- Consider bear upon to operation and equipment sizing associated with failure of energy recovery systems or filter loading.

- During the Pandemic, disable any Need Control Ventilation (DCV) and introduce the design exterior air flow to occupied spaces until further notice (including DOAS).

- Employ and employ outdoor air quality sensors or reliable web-based data for outdoor pollution information every bit office of the new ventilation functioning.

Filtration Design Criteria/ Guideline

- Follow 2019 ASHRAE- Applications Handbook, chapter viii, table 7 for minimum Filtration Efficiency

- Apply the highest Minimum Efficiency Reporting Value (MERV) filter for the HVAC units (local, central and DOAS) given limitations with increment force per unit area drop. MERV thirteen is the recommended minimum; MERV 14 is preferred; per Filtration and Disinfection Guidance consider HEPA filters in critical areas.

- Innovate terminal or portable, all electrical HEPA/UV Machines in each classroom

- Target highest achievable air change rate for units that volition not generate excessive noise or negatively affect space air distribution

- Ensure menstruation patterns maximize mixing of air in classrooms

Operation and Scheduling Guideline for Existing HVAC Systems during the Pandemic

- Cooling and Heating equipment - Change the start of functioning hours (e.g. change 6 am kickoff to 4 am) and run DOAS

- Cooling and Heating systems (Local, central)- Goal is to create a thermal lag and minimize HVAC operations when occupied

- DOAS Systems - Run DOAS units two hours before and subsequently occupancy

- Frazzle fans- Plow on Turn on when DOAS is running

- Simply applies to schoolhouse days not weekend operations

- Goal is to affluent the edifice with OA and positively pressurize the edifice

- Defended Outdoor Air Systems (DOAS) – Create "Minimum Transmission Sequence of Functioning"

- DOAS Systems – Operate in occupied mode (including normal or peak outside air charge per unit introduced to each infinite) to accomplish minimum of iii air changes of equivalent clean air supply. In cases where calculations cannot readily be completed, operate systems equally described above for minimum period of two hours prior to occupants re-inbound building.

- For DOAS units equipped with active, thermally operated desiccant dehumidifier, consult the manufacturer for safety operation.

- For new installations, designer should designate a "Purge/Flush" mode for operations to minimize the virus transmission via HVAC systems.

- Free energy Recovery Systems

- For DOAS equipment with potential for cross contamination from exhaust air stream to outdoor air stream, verify MERV-xiii filtration filters any air that may exist recirculated (may exist in exhaust intake position for some units).

- Many air treatment system types (central air handling units, DOAS units, last systems, etc.) include Free energy Recovery Ventilation (ERV) systems (these can include energy recovery wheels, plate-blazon heat exchangers, heat pipes, run around loops, etc.)

- Some types or configurations for energy recovery systems allow for exhaust air transfer from the exhaust airstream to the supply airstream, while others practise not – depending on arrangement configuration this may be cause for concern

- A document focused on operational considerations for energy recovery systems for many system types and configurations is bachelor.

- AHUs (SZ and VAV) and Packaged Rooftop units (PSZ, PVAV)

- During the Pandemic, increment Filtration to that recommended in the Filtration Upgrade section below.

- For existing units, an increment in filtration efficiency may reduce airflow capacity. Compensate for loss of chapters in wintertime with portable plug in elec. Heaters or higher discharge temps.

- Compensate for loss of capacity in summertime with lower discharge temps off of AHU – recommend 52 F (this is mainly for VAV units where supply air temperature is controlled and due to additional pressure level drop associated with college efficiency filters).

- Bank check and fix economizer dampers and controls and maximize the economizer functioning when possible (favorable outdoor conditions and outdoor air pollution).

- Bank check, fix and change control sequences in VAV systems to avert outdoor air flow /minimum OA air flow shortage.

- In VAV systems maximize the full supply air flow in each VAV concluding when the system is in full economizer way.

- Minimize the unit air recirculation to minimize zones cross contagion thru the render air arrangement.

- Consider air treatment technology to impale/disable airborne infectious aerosols (refer to the Building Readiness Document for additional guidance).

- Consider installing Humidifiers in AHUs and Packaged rooftop units if feasible. Consideration must exist given to climate zone and building envelope to avoid mold growth or IAQ problems.

- Install duct mounted humidifiers at classrooms as an alternate.

- Local HVAC units (Fan Coils, WSHP, GSHP, Mini Separate, VRF, Unit Ventilators, Radiators/baseboards)

- Increment Filtration to the maximum efficiency (highest MERV rating) recommended by the manufacturer.

- Compensate for loss of capacity in winter with portable plug in electric heaters or higher discharge temps.

- Hydronic /Electric radiators / baseboard should remain operational.

- Check unit ventilators for proper amounts of OA and operation.

- Consider installing portable humidifiers in each classroom for local humidity control if feasible. Consideration must be given to climate zone and edifice envelope to avoid mold growth or IAQ problems.

- Space Air Menses

- Where directional airflow is non required or recommended, verify air distribution promotes mixing of space air without creating potent air currents that increase direct manual from person-to-person

- Recommended guidance is to provide lowest possible particulate concentration anywhere in the space

- Consider upper air UV-C treatment for select spaces. Piece of work with a reputable ventilation engineer or UV system designer.

Nurses Office – General Requirements | Render to Summit

Temperature and Humidity Blueprint Criteria- Isolation Mode

- Winter Nurse Station pattern guidelines 72 F/50-55% RH

- Summer Nurse Station pattern guidelines 72 F/50%-60% RH

Ventilation Design Criteria/Guideline- Isolation Way

- 100 % OA organisation

- Design for a maximum of ten Air Changes per Hour (ACH), tin can operate at half-dozen ACH

Filtration Pattern Criteria/ Guideline- Isolation Mode

- Follow ASHRAE 170, tabular array 6.iv – Protective Environment (PE) room filter guidelines

- Two filter banks, MERV 7 and HEPA (MERV 14 for existing HVAC that is unable to back up HEPA)

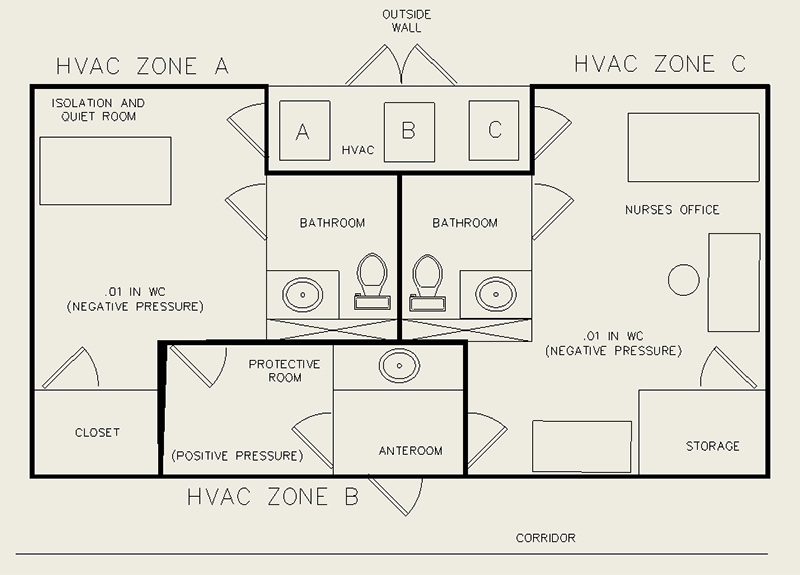

Space Pressurization Pattern Criteria/ Guideline- Isolation Style

- Follow ASHRAE 170, section 7.2 and other related sections for space pressure level requirements

- Isolation Room and Nurse role will be Negative Force per unit area (- 0.015" to – 0.05" W.C)

- Protective Room will be Positive Pressure level ((+ 0.015" to + 0.05" W.C)

- Given the small size of the systems serving the Nurse Station in Isolation Mode, it is suggested because Constant Volume, hard counterbalanced air system.

Space Air Distribution/Diffusion Design Criteria/ Guideline- Isolation Manner

- Follow ASHRAE 170, Tabular array 6.7.two – PE Group E non-aspirating (for additional information refer to 2017 ASHRAE – Fundamentals, chapter 20).

General Design Parameters- Isolation Mode

- Follow ASHRAE 170, Table seven-i

- Care for as PE lobby and combination AII/PE.

- ACH = 10.

- Exhaust directly to outdoors

- No air re-circulation

- All should be under negative pressure.

- PE rooms with respective to adjacent rooms should be under positive pressure.

- Follow ASHRAE 170, department vii.ii.1.

- Infection Control Gamble Assessment (ICRA) is to exist performed for new construction and renovations of nurse facilities.

- Refer to guidance on ICRA for renovations and creating a CX programme and well as phasing the construction.

- Follow ASHRAE 170, Section 6.8.two which refers to free energy recovery.

- No energy recovery for airborne infectious isolation rooms.

- Refer to section half-dozen.8.2 exception for cases where Energy Recovery can be applied.

Operation and Scheduling Guideline

- Isolation Style (Dedicated 100 % OA systems)

- Cooling, Heating, Humidification, Dehumidification, Ventilation – run two hours before and after occupancy

- Exhaust fans - run when ventilation is on

- Normal Way (Supplementary HVAC systems)

- Cooling, Heating, Ventilation - per normal school schedule(occupied/unoccupied or optimal start program)

- Exhaust fans - per normal school schedule (occupied/unoccupied), might be OFF during unoccupied hours

Filtration Upgrades | Render to Tiptop

Introduction

The focus of this section is to provide instructions for educational facility managers to increase their filtration efficiency in existing air systems on a temporary basis during the pandemic. The presentation focuses on filtration nuts for a facility manager, an information gathering phase, a data analytics and review phase and lastly a serial of implementation and considerations an educational facility manager may accost. Refer to the department on Filtration/Disinfection nether the COVID-19 resources from the ASHRAE Epidemic Task Forcefulness.

This guidance has been formulated to help designers and facility managers to retrofit and plan for the improvement of indoor air quality and to ho-hum the manual of virus via the HVAC systems. The underlying effort of the designer should be to increase outside air to the spaces, treat return air and or supply air to spaces via mechanical filtration or treating the air and maintain indoor comfort as defined by temperature and relative humidity.

The guidance should be applied to each unique climate zone, unique school building and HVAC system. All retrofits and modifications must not contradict ASHRAE 62.1 guidelines and must continue to come across code. The designer needs to piece of work closely with the local school system to work in conjunctions with new operational protocols and school operations.

Filtration Nuts | Return to Peak

Key Terminology for Filtration

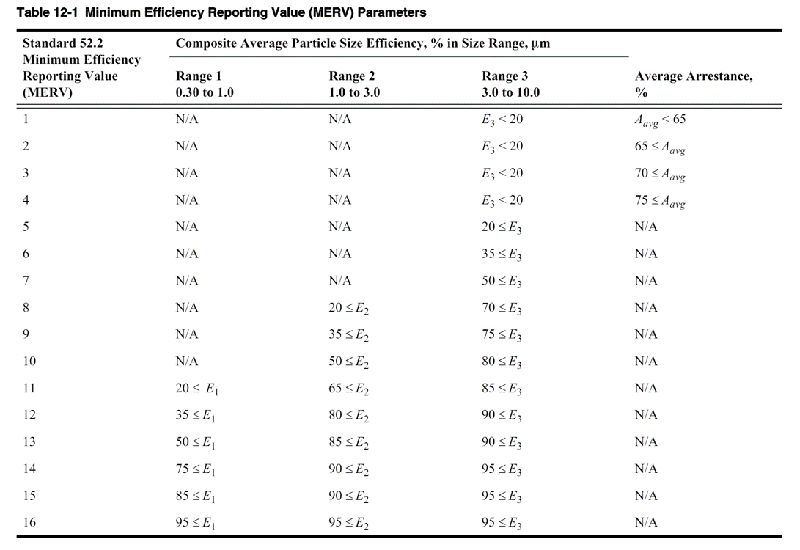

- MERV Rating – Minimum Efficiency Reporting Values, or MERVs, study a filter'southward ability to capture particles between 0.3 and ten microns (µm).

- For filters with enhanced performance using static charge, consider MERV-A ratings to understand performance of filter if accuse has been removed or dissipated.

- Particle Size Range – This is the composite particle size efficiency percentage inside a range of particle size. The three ranges used in Std 52.2 are E1 - (0.3-one.0 µm), E2 - (1.0-iii.0 µm), and E3 – (three.0-x.0 µm).

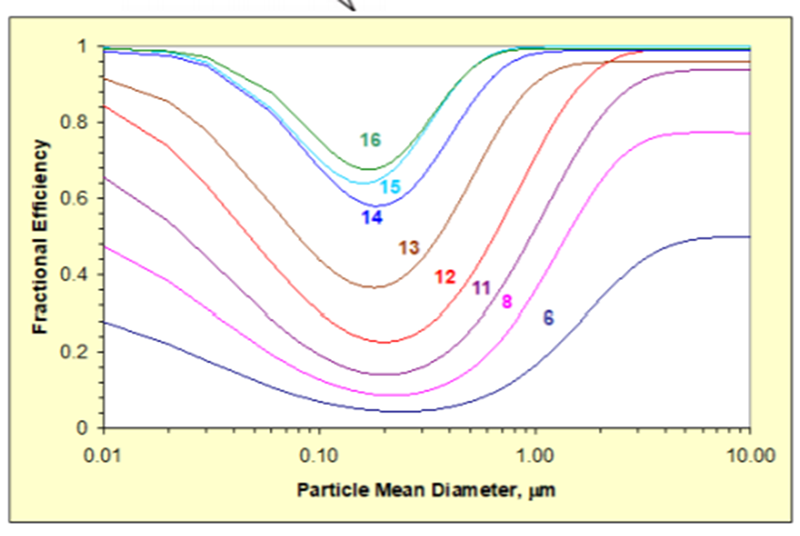

Mechanical Air Filters

- Consist of media with porous structures of fibers or stretched membrane material to remove particles from airstreams. Filters range in size but the typical depths of filters are 1", ii", 4" and 12-xv".

- Some filters have a static electric accuse applied to the media to increase particle removal.

- The fraction of particles removed from air passing through a filter is termed "filter efficiency" and is provided past the Minimum Efficiency Reporting Value (MERV) under standard conditions.

- MERV ranges from i to xvi; higher MERV = higher efficiency

- MERV ≥thirteen (or ISO equivalent) are efficient at capturing airborne viruses

- Generally, particles with an aerodynamic bore around 0.3 μm are most penetrating; efficiency increases above and below this particle size.

- Overall effectiveness of reducing particle concentrations depends on several factors:

- Filter efficiency

- Airflow rate through the filter

- Size of the particles

- Location of the filter in the HVAC system or room air cleaner

ASHRAE Standard 52.two-2017 -- Minimum Efficiency Reporting Value (MERV)

Filtration Target Level | Return to Top

Target Level for Filtration for Schools is MERV 13 or college.

Significant improvement in removal when compared to MERV eight

Filtration Upgrades: Information Gathering Phase | Return to Tiptop

Data Collection Stage – Can exist washed past any staff

- Determine if the Edifice was CHPS Certified.

- Determine the current size, depth and quantity of filters in equipment. Make a listing by piece of equipment.

- Decide if there are one or two filter banks.

- Document MERV rating of existing filters installed. May need to review previous filter orders.

- Decide the expanse of filter banks. This can also exist adamant by quantity of filters broken down by size of filter.

- Collect Original Design Drawings if available.

- Gather equipment shop drawings or Operation and Maintenance Manuals.

- Record the Model or Series number of the air handling equipment.

- Decide the type of motor that is used in the equipment.

- Make up one's mind if the equipment served from a Variable Frequency Drive.

Tape all Data Collected

Filtration Upgrades: Data Analysis & Review | Return to Top

The following are steps for Data Assay:

- If the system is designed for MERV 13 filters, and MERV xiii filters are not in place, alter filters to MERV 13.

- If the existing filters and filter bank are two" or thicker install a MERV xiii Filter. Make up one's mind if a i" rack can be refitted with a larger rack.

- If filter racks can accept a minimum MERV xiii filter but were non part of the original design, the following analysis can exist completed by internal staff or a consulting engineer:

- Provide Information previously gathered in the Gathering Phase to private completing boosted analysis.

- Summate the velocity of the existing filter bank to make up one's mind existing filter pressure level driblet when make clean.

- Typical Velocity is betwixt 300-500 fpm.

- Determine the initial and final pressure driblet for the filters in the original organisation blueprint.

- Summate the increment in filter pressure drop after installing the new MERV 13 filters. Think the final pressure drib of any filter is an operational choice.

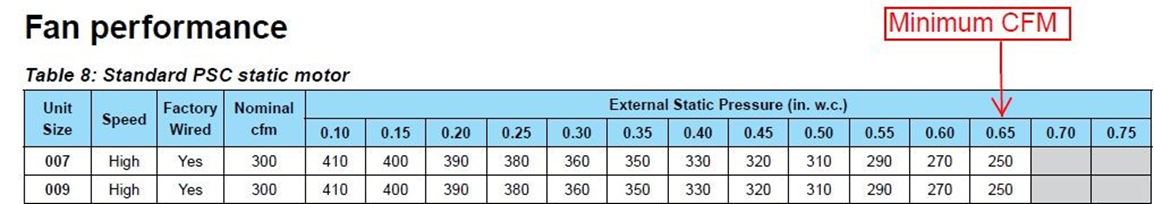

- Review the original design and equipment shop drawings to determine available External Static Pressure for equipment.

- Determine the effect of additional external static pressure on the fan.

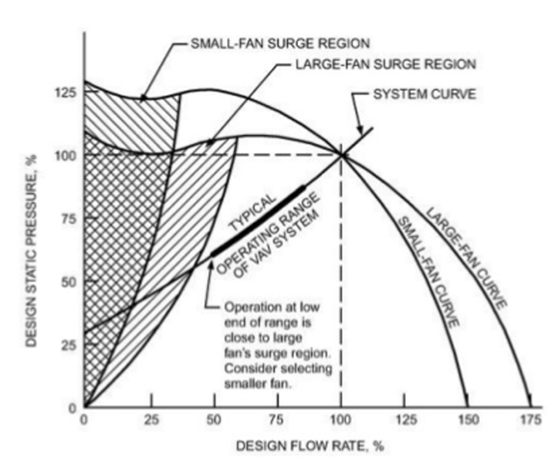

Motors and Fan Curves

- Determine if the fan speed can be increased to compensate for the additional force per unit area drop while maintaining the required airflow.

- Decide if the speed increase exceeds the fan maximum tip speed.

- Determine if the speed increment exceeds the maximum motor power.

- Fan airflow is reduced with increase in filter restriction. This may lead to DX low suction pressures which causes faults in cooling or DX high pressure level trips in heating with HP's. Electric heat elements must accept sufficient airflow to operate.

- A constant cfm ECM fan will exist noisier with brake. Could increase noise in infinite and have a negative impact to the acoustics of the space.

- Be aware of fan surge under increased static pressure level and low menstruation rate.

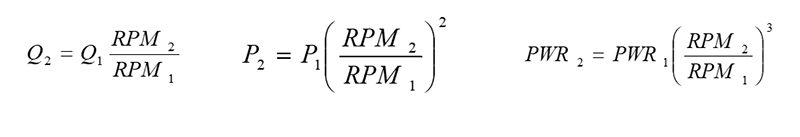

Fan laws are relatively straightforward:

Q = Menstruum

P = Pressure

PWR = HORSEPOWER

RPM = FAN SPEED

Filtration Upgrades: Implementation & Considerations | Render to Acme

What are the next steps?

- If MERV thirteen filters are installed in the existing equipment and then guild additional filters for future filter changes.

- Filter Rack Maintenance and Replacement:

- If filter rack is damaged so repair rack,

- Ensure filter rack is sealed to prevent featherbed of unfiltered air,

- Review seal installation procedures with maintenance and operations staff,

- Replace and Upgrade Rack if possible, to accept a filter with a higher MERV rating.

- Consider changing out motor to increase static pressure bachelor, merely this may require significant electrical modifications.

- Suit the Variable Frequency Drives to address increase in static pressure for filters.

If MERV 13 Filters cannot be installed consider the following:

- Increment the filtration in the unit of measurement to the maximum available

- Provide a recirculation fan filtration unit and duct into the render of units

- Provide a HEPA filtration unit which re-circulates air within the infinite

- Consider additional treatment applied science to kill/disable airborne infectious aerosols (refer to Edifice Readiness Document for boosted guidance)

- Refer to ASHRAE Filtration and Disinfection system section for additional information

- Consider alternate filter locations in return duct or grille but consider static pressure level driblet implications and relationship with outside air dampers

Additional Considerations:

- Install a pressure estimate on units to aid in determining filter change frequency

- Document motor amperages earlier and after filter changes, alert points in BAS may need to be updated

- Filter change frequency may increment due to seasonal and atmospheric considerations at different sites (such as Pollen Season)

- There will be an increase in fan energy used to overcome additional pressure drop from filters

- With an increase pressure driblet for filtration there volition be less airflow to heat and cool the spaces during summit design days

- Additional supplementary heaters or cooling devices may be required.

HVAC System Maintenance and Filter Replacement during the COVID-nineteen Pandemic:

- For HVAC systems suspected to exist contaminated with SARS-CoV-ii, it is not necessary to suspend HVAC organisation maintenance, including filter changes but additional safety precautions are warranted

- The risks associated with handling filters contaminated with coronaviruses in ventilation systems under field-utilise conditions have not been evaluated

- Workers performing maintenance and/or replacing filters on any ventilation system with the potential for viral contamination should habiliment appropriate personal protective equipment (PPE)

- When feasible, filters can be disinfected with a 10% bleach solution or another advisable disinfectant, approved for utilize against SARS-CoV-2, before removal. Filters (disinfected or not) can exist bagged and tending of in regular trash, or applicable local health and prophylactic standards

- When maintenance tasks are completed, maintenance personnel should immediately wash their hands with soap and water or use an booze-based manus sanitizer.

Operation of Occupied Facilities | Render to Top

- Measure out/Tendency all information possible, including temperature (dry bulb), relative humidity, carbon dioxide concentration, zone population, etc. - may be done with central Building Automation System (BAS) if available - mobile/handheld devices may exist used if fundamental monitoring not available.

- Follow up on temperature control, humidity control or elevated carbon dioxide concentration issues observed to address cause(s).

- Certificate whatsoever unusual observations other than those that can be recorded by control systems.

- Share pertinent information between all appropriate groups: Maintenance, Free energy, Environmental Health & Safety, Building Managers, Administration, etc.

- Create reporting methodology for tracking and reporting of critical infections. Develop policies for utilise of drinking fountains/water coolers.

- Develop policies for lockers or storage spaces.

- Develop maintenance policies for new/added equipment such as local air cleaners, humidifiers, boosted filtration in mechanical equipment, etc.

Controlling Infection Outbreaks in Schoolhouse Facilities | Return to Meridian

- Identify symptoms in Student.

- Provide PPE and remove suspect individual – relocate to nursing or isolation space.

- a. A Thou-12 Facility should develop a policy to isolate the student near the nurse'southward function in a room described in this guidance, inform parents and release symptomatic pupil according to that policy.

b. Higher pedagogy facilities should isolate that pupil at the Student Health Facility in a room described in this guidance until that student tin can either safely travel dwelling house or exist transported to a medical facility, if necessary. - Notify advisable individuals (either parents or students) about possible contact.

- Develop protocol to handle quarantine of other individuals who may have been exposed, wash/sanitize belongings and impacted spaces, look at potential for spread to adjacent spaces or other building areas through mechanical systems or other ways.

- Develop protocol to handle air cleaning for space prior to re-occupying.

- Report/track incident through defined policies.

College Education Facilities

Educatee Health Facilities

Screen patients entering dispensary in waiting surface area

- Establish physical barrier in waiting room for screening

- Require confront mask and hand sanitation from a sanitizer dispenser

- Increment ventilation rate six ACH clean air

- Create at least one isolation exam room in waiting area (can be temporary)

- Add non-woven fabrics for seating

- Utilise laminate or solid surface casework to amend cleaning

- Remove carpet for flooring

- Isolation rooms – Follow ANSI/ASHRAE/ASHE Standard 170

- Negative Force per unit area to 0.01 inches of water

- Twelve air changes (HEPA recirculation immune)

- All air exhausted to outdoors (exhaust grill above examination table)

- Provide minimum ii isolation rooms (conduct risk cess)

- Defended HVAC capable of 100% OA

- Foyer/Protective Equipment Room

- Normal non-isolation nurses office tin can become iso-room

- Include Biohazard waste material storage in vestibule and iso-room for PPE

Temporary Isolation Rooms during Pandemic in improver to waiting room

See layout suggestion here, can be modified as needed

Laboratories | Render to Top

Education Facilities contain a wide range of laboratory spaces with different functions and operational requirements

- Refer to Laboratory Guidance from ASHRAE Epidemic Job Strength for specific space recommendations

Source: https://www.ashrae.org/technical-resources/reopening-of-schools-and-universities

Belum ada Komentar untuk "Who Creates the Final Pre Incident Plan Drawings"

Posting Komentar